Sometimes off-the-shelf controllers just don’t quite do the job. Fortunately, the ROI of a custom engineered solution is often much better than the off-the-shelf solution.

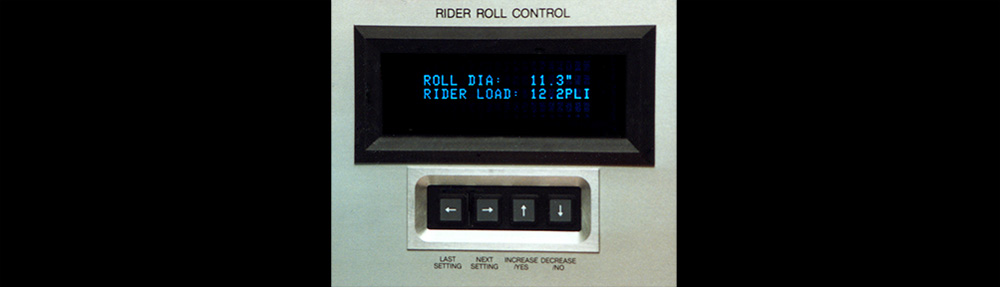

Shown above is a Rider-Roll controller, used in pulp (paper) mills on pulp winders. It uses an off-the-shelf micro-controller board, along with a custom designed interface board, and custom firmware written in C. When winding pulp or paper into a roll, a “core” is placed on two powered rollers. A third roller, a “rider-roll’, presses down on the core to increase friction between the core and the powered rollers. As the roll approaches five feet in diameter, the weight of the roll plus the weight of the rider-roll may cause the pulp or paper to crinkle. The Rider-Roll controller causes a pneumatic cylinder to “off-load” some of the rider-roll weight gradually as the roll of pulp grows.

Above is an Interface Control Unit, developed for the Federal Aviation Administration (FAA), New England Region, and used at the Worcester, Massachusetts airport to control Glide Slope and Localizer transmitters. Some features include push-buttons with LCD legends and red/green/yellow LED backlights that the firmware fully controls. The hardware was designed by a contractor to the FAA, and the firmware was developed in “C” by Productive Technology.

Developed the embedded code in “C” for PID (proportional–integral–derivative) controller. This was designed for controlling a gas burner’s start-up, output and shutdown. It used two analog inputs and two analog outputs to sense and control batch temperature and a 4×20-character display and keypad for operator input via menus, six digital inputs for interlock and status, and four digital outputs for control and status display. Communication to the display/keyboard was via RS-232.